Plywood

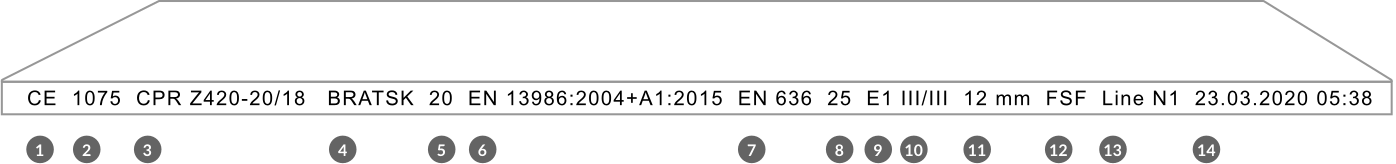

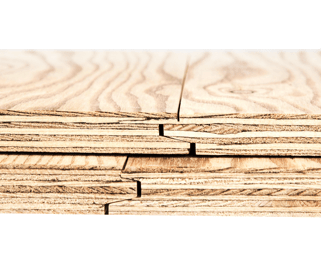

General-purpose plywood with outer plies from SPF, sanded and unsanded, branded FSF, is produced at the Ilim Timber sawmill in Bratsk, according to GOST 3916.2.-2018.

Durable and resilient

In terms of flexural strength, Angara pine and Siberian larch are similar to or better than birch. Both species are also more resilient to external factors.

Moisture-resistant and environmentally safe

State-of-the-art waterproof, eco-friendly E1 adhesives and veneer layers of Siberian softwood ensure excellent resistance to moisture and environmental sustainability.

Distinctively unique texture

The outer plies of Siberian larch have a distinctive and unique texture. The Ilim Timber mill in Bratsk is the only large-scale manufacturer of plywood of this type.

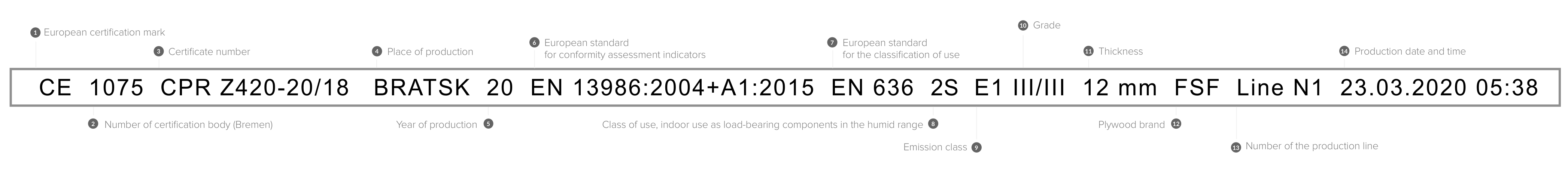

Specification

Brand

FSF, enhanced water-resistance

Grade (quality of outer plies)

I/I, II/II, I/II, I/III, II/III, III/III

Emission class

E1

Size, mm

2,440 × 1,220; 2,500 × 1,250

Option

Tongue and groove (T&G)

Thickness, mm

6,5; 9; 12; 15; 18; 21

Surface treatment

Untreated, sanded

Species

Pine, Larch

Edging mark

Labelled Ilim Timber

6.5 mm

3 plies

9 mm

3 plies

9 mm

5 plies

12 mm

5 plies

15 mm

7 plies

18 mm

9 plies

21 mm

11 plies

24 mm

11 plies

27 mm

11 plies

30 mm

13 plies

Areas of application and grades

FSF softwood plywood with enhanced water-resistance and durability is suitable for a wide range of outdoor and indoor applications.

Plywood grades are assigned according to the visual surface quality which depends on natural wood properties of face veneer layers

1st grade

1st grade

1st grade (I/I, I/II, I/III) meets the most stringent requirements for visual appearance and strength properties and is best suited for furniture fronts as well as for interior and exterior design.

2nd grade

2nd grade

2nd grade (II/II, II/III) meets strict requirements for surface quality and strength properties and is best suited for a wide range of furniture and interior elements as well as for subfloors, underlayments and laminate cores.

3rd grade

3rd grade

3rd grade (III/III, III/IV) is used in construction, interior design and packaging as a durable, water-resistant material that doesn’t have to meet high requirements for surface appearance.

Specialty products

Хвойная фанера шип-паз (T&G2)

Softwood tongue and groove plywood (T&G2)

Tongue and groove plywood is used as an easy-to handle material in roofing, flooring, panelling and similar constructions to provide for a single flat and smooth surface. T&G plywood is manufactured on precision machines from Homag (Germany).

Хвойная фанера сорта I+/II с наружным слоем из сибирской лиственницы

Softwood plywood, I+ grades with outer layer of Siberian larch

Softwood plywood, I+ grades with outer layer of Siberian larch (Larix Siberica) is used for furniture and interior design. Bespoke texture, durability and resilience offer a unique combination of aesthetic and construction benefits in one product.

Areas of application

Construction

- Formwork

- Roof and wall sheathing for roof and walls

- Subflooring

Transport

- Flooring

- Lining for vans and carriages

Packaging

- Pallets

- Industrial packaging

- Containers

Furniture and decor

- Furniture

- Interior design and decorative elements

- Base for parquet flooring

Other

- Billboards

- Playgrounds

- Toys

Physical and mechanical properties

Property name

Thickness, mm

Value

Property name

Moisture content, %

Thickness, mm

4 — 30

Value

5 — 10

Property name

Ultimate static bending strength parallel to grain orientation of face veneer sheets, MPa, minimum

Thickness, mm

9 — 30

Value

30

Property name

Ultimate tensile strength parallel to grain orientation of face veneer sheets, MPa, minimum

Thickness, mm

6,5 — 30

Value

20

Property name

Modulus of elasticity in static bending parallel to grain orientation of face veneer sheets, MPa, minimum

Thickness, mm

9 — 30

Value

7000

Property name

Impact viscosity in bending, kJ/m2

Thickness, mm

9 — 30

Value

34

Property name

Hardness, MPa

Thickness, mm

9 — 30

Value

20

Property name

Thermal conductivity factor (W/mK), at average density, kg/m3

4 — 30

Property name

Thermal conductivity factor (W/mK), at average density, kg/m3

300

Thickness, mm

4 — 30

Value

0,09

Property name

Thermal conductivity factor (W/mK), at average density, kg/m3

500

Thickness, mm

4 — 30

Value

0,13

Property name

Thermal conductivity factor (W/mK), at average density, kg/m3

700

Thickness, mm

4 — 30

Value

0,17

Property name

Thermal conductivity factor (W/mK), at average density, kg/m3

1000

Thickness, mm

4 — 30

Value

0,24

300

0,09

500

0,13

700

0,17

1000

0,24

Property name

Water vapour resistance factor under wet cup, at average density, kg/m3

4 — 30

Property name

Water vapour resistance factor under wet cup, at average density, kg/m3

300

Thickness, mm

4 — 30

Value

50

Property name

Water vapour resistance factor under wet cup, at average density, kg/m3

500

Thickness, mm

4 — 30

Value

70

Property name

Water vapour resistance factor under wet cup, at average density, kg/m3

700

Thickness, mm

4 — 30

Value

90

Property name

Water vapour resistance factor under wet cup, at average density, kg/m3

1000

Thickness, mm

4 — 30

Value

110

300

50

500

70

700

90

1000

110

Property name

Water vapour resistance factor under dry cup, at average density, kg/m3

4 — 30

Property name

Water vapour resistance factor under dry cup, at average density, kg/m3

300

Thickness, mm

4 — 30

Value

150

Property name

Water vapour resistance factor under dry cup, at average density, kg/m3

500

Thickness, mm

4 — 30

Value

200

Property name

Water vapour resistance factor under dry cup, at average density, kg/m3

700

Thickness, mm

4 — 30

Value

220

Property name

Water vapour resistance factor under dry cup, at average density, kg/m3

1000

Thickness, mm

4 — 30

Value

250

300

150

500

200

700

220

1000

250

Property name

Noise absorption factor, dB, in frequency range, Hz

4 — 30

Property name

Noise absorption factor, dB, in frequency range, Hz

250–500

Thickness, mm

4 — 30

Value

0,10

Property name

Noise absorption factor, dB, in frequency range, Hz

1000–2000

Thickness, mm

4 — 30

Value

0,30

250–500

0,10

1000–2000

0,30

Property name

Sound insulation, dB

Thickness, mm

6,5 — 30

Value

23,0

Property name

Biological stability, hazard class

Thickness, mm

4 — 30

Value

4f, DHy, Sa, St

Property name

Flammability rating

Thickness, mm

4 — 30

Value

according to GOST 30244

Formaldehyde content in plywood and formaldehyde release into the room air depending on the emission class:

Emission class

Formaldehyde content per 100 grams of absolutely dry weight of plywood, mg

Formaldehyde release

Chamber method,

mg/m3 of air

Gas analysis method,

mg/m2 /h

Emission class

E1

Formaldehyde content per 100 grams of absolutely dry weight of plywood, mg

Up to 8.0 inclusive

Formaldehyde release chamber method, mg/m3 of air

Up to 0.124

Formaldehyde release gas analysis method, mg/m2 /h

Up to 3.5 inclusive or less than 5.0 within first three days after manufacturing

Useful links

Websites

www.ic.fsc.org